- tungsten, molybdenum, tantalum, niobium and rhenium,

ods-copper,cemented carbide.

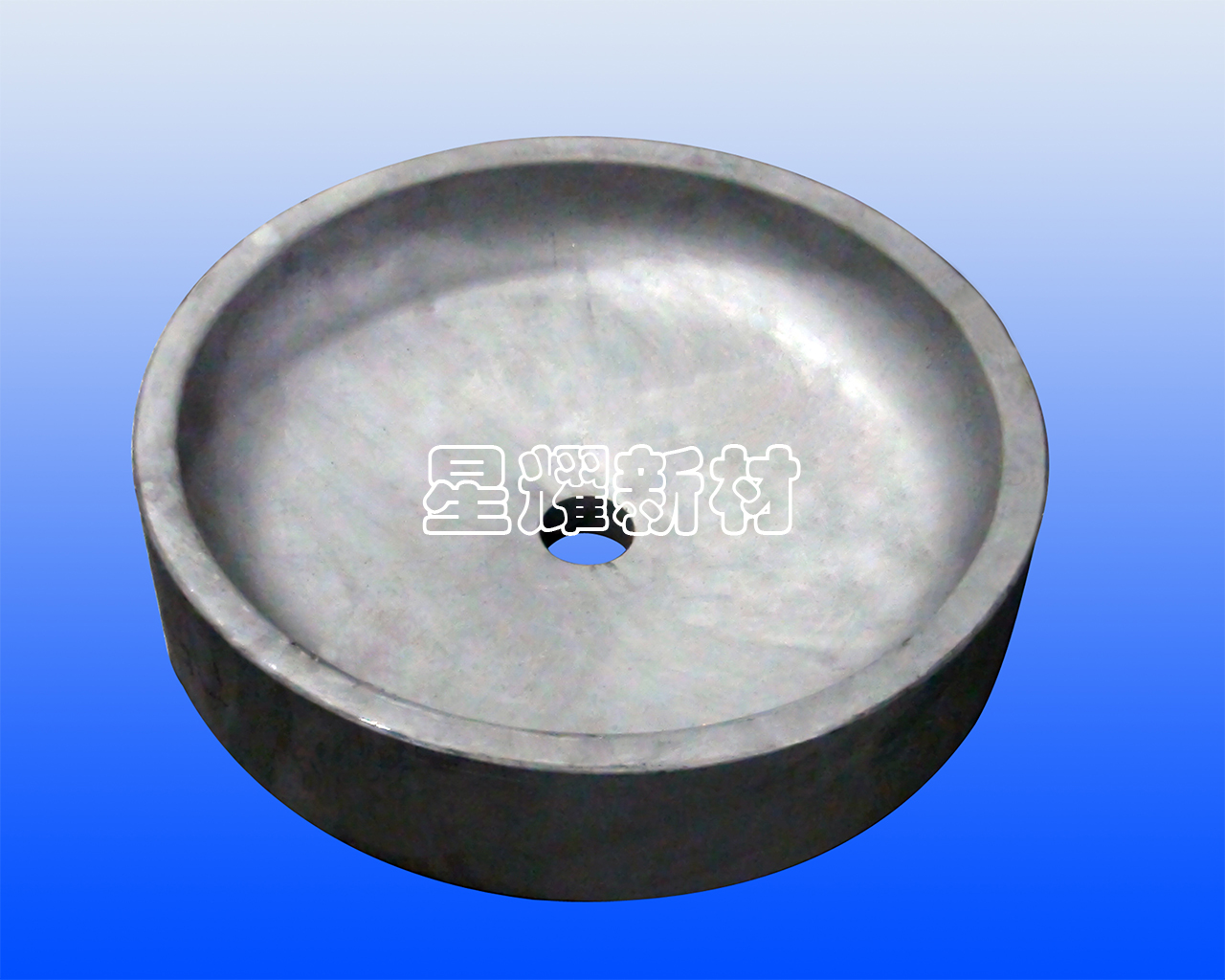

Quartz Continuous Melting Furnace

Application:

Application:

Quartz glass is silicon dioxide constituent of glass whose hardness can reach Morse seven levels. It has a series of excellent physical and chemical properties: high temperature resistance, low expansion coefficient, heat shock resistance, chemical stability and good electrical insulation, and ultraviolet and infrared lights can pass through.

Material Properties:

Material Properties:

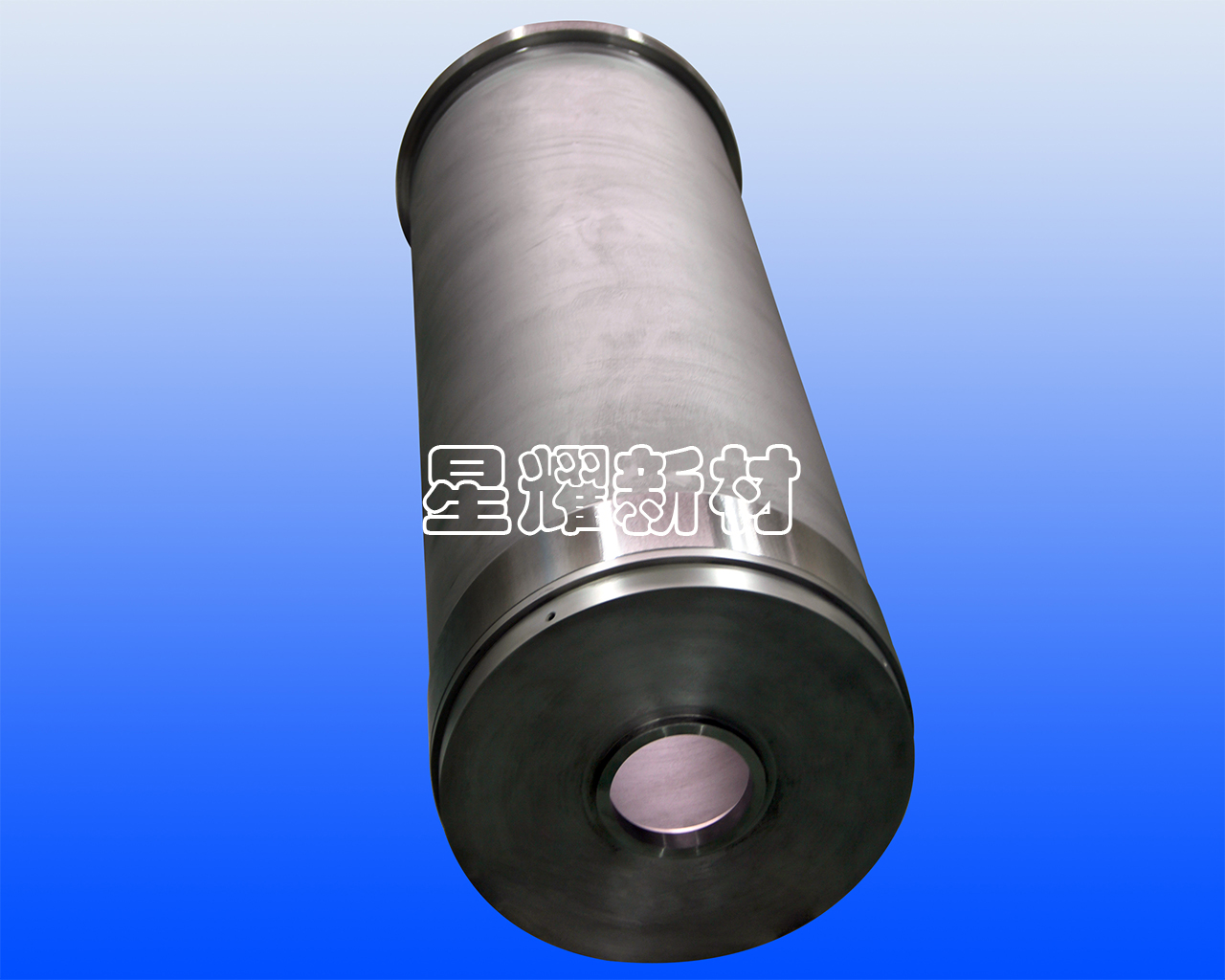

Tungsten has the characters of high melting point, high strength at elevated temperature, low electrical resistivity, lower thermal expansion, low work function of electron emission and low vapor pressure.

- Tungsten Heater

- Tungsten Shields

- Fabricated Tungsten Parts

Product specification:

Product specification:

Tungsten Tubes: we can produce the largest tungsten tube in the world. OD=780mm

Conventional Density: 17.8 g/cm3-18.3 g/cm3

Special Process Density: ≥18.5 g/cm3

Typical Specifications of Tungsten Tube:

Diameter(mm)

Wall Thickness(mm)

Length(mm)

≥30

≥2

≥1300

≥150

≥5

≥300

≥10

≥400

≥15

≥800

≥35

Note: All sizes of tungsten tubes can reach high precision by machining.

Tungsten Mandrel Shalfs: After forging,the length of Mandrel Shalfs can be L≤2500mm, Diameter≤80mm.